-

Categories

-

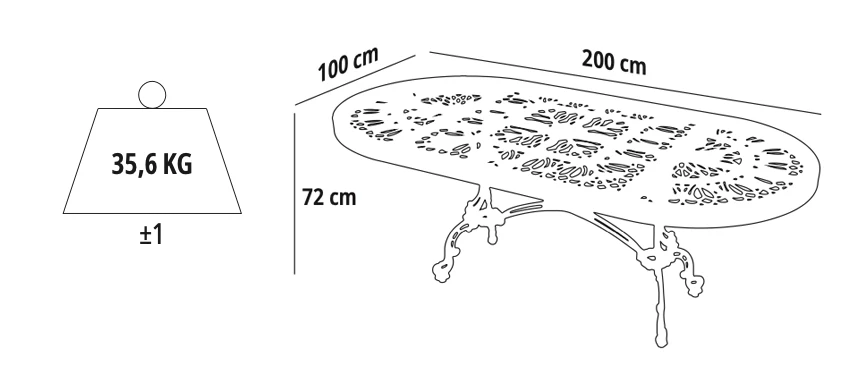

Furniture and Decoration

Furniture and Decoration

-

Sports and Outdoor Products

Sports and Outdoor Products

-

Printing and Publishing Products

Printing and Publishing Products

-

Marble and Natural Stone Products

Marble and Natural Stone Products

-

Construction and Building Materials

Construction and Building Materials

-

Industrial Products and Machines

Industrial Products and Machines

-

Food and Agricultural Products

Food and Agricultural Products

-

Automotive and Spare Parts

Automotive and Spare Parts

-

Household and Kitchen Products

Household and Kitchen Products

-

- Home

-

Brand

-

-

( 3 )

-

( 606 )

-

-

( 4 )

-

( 3 )

-

( 35 )

-

- Discounted products

- All vendors

- Sign in

- Sign up

-

Furniture and Decoration

Furniture and Decoration

-

Sports and Outdoor Products

Sports and Outdoor Products

-

Printing and Publishing Products

Printing and Publishing Products

-

Marble and Natural Stone Products

Marble and Natural Stone Products

-

Construction and Building Materials

Construction and Building Materials

-

Industrial Products and Machines

Industrial Products and Machines

-

Food and Agricultural Products

Food and Agricultural Products

-

Automotive and Spare Parts

Automotive and Spare Parts

-

Household and Kitchen Products

Household and Kitchen Products

-

Textiles and Clothing

Textiles and Clothing

-

Health and Medical Products

Health and Medical Products

- View All